Introduction

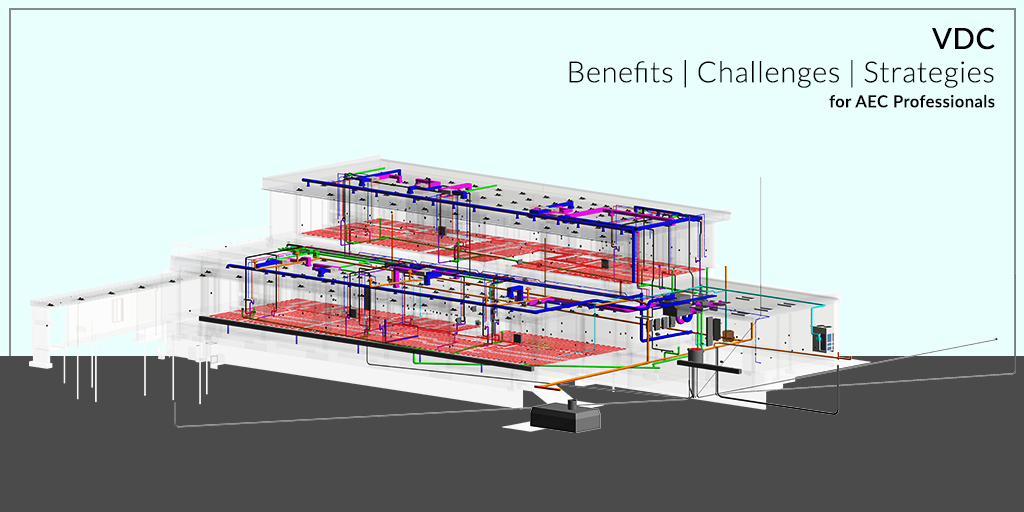

The implementation of a Virtual Design and Construction (VDC) approach to projects has begun to be promoted by leading members of the Architecture, Engineering & Construction (AEC) industry, a move that slowly but radically changes the way projects are completed. VDC defines the mechanism by which each phase of a construction project is collaboratively simulated by the design and construction team before beginning work on the actual job site.

It’s a drastic move made by the industry just as the move from pen-and-paper blueprints to CAD drawings, but one that brings widespread changes in productivity and quality across all facets of a project. VDC continues with the use of Building Information Modeling (BIM) solutions but goes far beyond new technology adoption. The emphasis is on data-driven project collaboration, where all project participants collaborate to deliver a project that is on budget, on time, and exactly as planned by the owner. VDC and BIM helps participants of the project to collaborate in a shared language, where all relevant knowledge is clear and accessible immediately. Proactively and cooperatively, problems are addressed.

As the advantages of construction projects are becoming better known in the AEC industry, a growing number of owners are demanding that uniquely complex projects be completed in less time than ever before. With these aspirations, designers, general contractors, specialty contractors, fabricators, and other partners will soon find that the only way to survive the evolution will be to implement VDC and other new methods for approaching projects.

Why VDC is Important?

Forward-thinking business leaders are constantly finding ways to reach new levels of profitability, and profitability is based on delivering results on time and on budget for design and construction professionals.

The AEC industry is moving swiftly in the direction of VDC. The digital environment enables experts to handle projects more holistically and serves as a foundation for significant changes in performance. Industry leaders have already switched to a VDC approach, setting the course for a future where owners only require results via a collaborative virtual platform.

Don’t have the time to read the whole blog, no worries you can download it and read it at your convenient time.

What is VDC Construction Meaning?

Virtual Design and Construction (VDC) is the mechanism by which design and construction partners collaboratively simulate all work in a 3D virtual environment on a construction project before doing any on-site, real-world work. In order to achieve the desired result, VDC enables project partners to handle all aspects of a project more efficiently, from schedule to budget to material procurement and so on.

The five elements that enable VDC are:

1. Building Information Modeling (BIM)

BIM is a process that facilitates collaboration on a consolidated 3D model. This 3D BIM model “is a digital representation of physical and functional characteristics of a facility. As such, it serves as a common knowledge resource for a facility’s information, forming a reliable basis for decisions from the beginning onwards during its life cycle. (National BIM Standard, National Institute of Building Sciences)

Input from all partners is included in a proper BIM model, which is crucial to VDC’s success. In reality, with the use of a single parametric model, VDC can achieve more efficiency. Accordingly, with BIM Level 3—the highest level of BIM maturity and the industry’s aspirational goal—all parties work collaboratively on a single, parametric BIM model.

Related Article: What is Building Information Modeling (BIM)?

Related Article: 3D CAD, BIM & VDC | Difference, Scopes and Applications

2. Level of Development (LOD)

Level of Development indicates the reliability of the output, or “the degree to which the element geometry and attached information have been thought through.” It is not to be confused with Level of Detail (which indicates “how much detail is input into the model element”). (Level of Development Specification, BIM Forum)

Inside each model element, the LOD Specification helps anyone working on a construction project to clearly understand the desired depth and quality of details. Usually, the VDC process begins at LOD 100 and goes up to LOD 350 or higher, providing the degree of precision required to predict how MEP-FP systems would communicate.

An element with LOD 350 or higher is where nearby or attached elements— such as supports, connections, and other parts necessary for coordination—are modeled. “The quantity, size, shape, location, and orientation of the element as designed can also be measured directly from the model without referring to non-modeled data such as notes or call-outs of dimensions.” (Level of Development Specification, BIM Forum)

Therefore, LOD 350 to 400 enables the project team to identify system conflicts and fabrication challenges before construction even begins—a key benefit of VDC.

Related Article: BIM Level of Development (LOD) 100|200|300|350|400|500

3. Advanced digital tools

Augmented Reality or Virtual Reality (AR/VR) can strengthen collaboration between all project participants on topics ranging from safety training to prepare for logistics to occupant experience. AR/VR applications are getting more advanced and popular. They are useful for advanced elements of a VDC method for visualization but are not an absolute necessity.

4. Collaboration space

A “virtual project site” or online meeting room allows all participants to contribute to the construction process, particularly the handoff between trades, and to alter and simulate it. This collaboration is better enabled by cloud-based environments because of the vast volumes of data that must be exchanged among all parties.

5. Collaborative mindset

It is important to note that both design and construction partners are involved in the project’s good outcome as a whole, and not solely as a result of their particular contribution. This is a key guiding principle for VDC.

VDC facilitates a collaborative approach to challenges through a joint team mindset founded on trust and mutual respect, welcomes constructive feedback, and respects mutual responsibility, where there are no silos, and where each member of the team celebrates the achievements of the other.

These principles of trust and co-dependence are above and beyond any formal contract or Integrated Project Delivery agreement.

Benefits of VDC: What Can Be Gained?

Clarity of communication through a single shared platform

It is as powerful to use a single platform as to share a common language; it brings the team to a point of clarity faster. As every participant is actively working with the same resources, opportunities, and constraints, it strengthens the principle of teamwork. This commonality enables team members to build upon the progress of each other and reach a level of success celebrated by the entire group.

Critics argue this strategy leads to a loss of creativity and a lack of opportunities for the unique solutions gained. Each participant takes a different route to the same finish line, making this claim flawed.

VDC is not about finding innovative ways to communicate; it is about pursuing quality communication and clarification.

Streamlined exchange of information via the cloud

The next, and perhaps most significant, step in the evolution of communications is cloud-based interaction: First, hand sketches and balsa models were held in a commonplace. Next, computer-aided drafted drawings were sent via floppy disc to different users. Then, 3D models of surfaces, lines, and letters (essentially CAD drawings in 3D) were transmitted to different users via zip drives and often, very slowly, via Internet connections. More recently, via email, shared files, and zip drives, 3D models of parts that communicate with each other are transferred to other parties; opened, downloaded, checked, and tampered with; and then sent back to the originator through the same email, directory, or zip drive process.

Today, multiple disciplines can simultaneously create, enhance, and maintain 3D models on a single platform through the cloud, giving them the ability to instantaneously review, and comment on the model.

A stronger extended team: from coordination to collaboration

Coordination is about each person doing their job and timing it all out to encourage others to do their jobs. Each team member is waiting for a job to be done, just like a relay race, so they can perform their part. The weakest link significantly impacts teamwork. The result is that many parties emphasize the value of “doing their job” over setting the team up to succeed.

Collaboration is about incorporating the abilities of every participant into each stage of development and enabling an early impact. Collaboration places emphasis on the end-product when performed correctly. There is less focus on individual success in collective teams and more attention on group success.

“Large-scale collaboration is the new normal. Your firm’s Project Team is now working at various levels with parties who, just a few years ago, did not participate in the coordination process.”

— David E. Quigley, Achieving Spatial Coordination Through BIM

Achieve team success (not individual wins) with aligned incentives

Over time, each stage of design has developed into its own unique business venture through construction. Entire industries have evolved around each aspect of the process. As a result, design and construction processes have become compartmentalized, and the bridges connecting each phase have become less robust.

Having a business strategy for success that is detached from the role of others in the process is normal for each discipline. Financial benefits do not always rely on the willingness of one to plan successors for a good outcome of the project. On projects that stretch for several months or years, this becomes much more evident and troublesome.

The idea behind VDC is to draw the key disciplines and champions of the various stages of the building process to a commonplace at the earliest reasonable stage, and maintain connectivity throughout the building lifecycle. In a way, the bridges are gone and replaced by a continuous highway.

A key advantage to this approach is the ability to focus on the end state, opening opportunities to innovate and, create more value during the earliest stages of design and planning.

Trust through transparency

All operation depends on trust in a collaborative, single-source network environment: trust that the partners have the same final aim in mind, trust that all stakeholders recognize the need for mutual progress, trust that when conflict occurs (and it will… often) the collective goal is achieving agreement rather than legal representation.

Trust in this type of environment means risk sharing, and in the construction world, this is not a common situation. Each group sees what the other is doing, both team members can ask for clarity when it is needed, and everyone is responsible for keeping the values of construction operation on track for each other.

An environment that supports problem solving

A creative idea for how to improve a design or process often lacks internal support due to an inability to prove a direct benefit. Too often within a project, an innovative solution is viewed as not adding value, and thus not worth exploring. Common reasons include, “We don’t have enough time or resources,” and “We cannot take a chance on a new approach, let’s stick to the standard.”

Method changes and innovative ways to do things are more readily embraced in a high-trust community. In a collaborative environment, innovations and process improvements are able to start small and grow with the project.

Greater value from early value engineering

In a collaborative effort, where designers and builders influence all the various stages to better define the project early on, smarter decisions can be made with a clearer and more accurate budget. For example, if a highly efficient concrete shell model is built at the earliest realistic point possible, at an earlier stage, the concrete supplier will provide a more specific price to the design team. This might free up contingency dollars to retain the project’s more fascinating elements. Thus, value engineering occurs earlier and can be used to eliminate components that are not added to the value.

VDC Challenges: What to Overcome?

Adoption of VDC is not an easy road. There are a number of obstacles to overcome.

The misperception that information must be restricted

Strong entities tend to dominate the process in today’s construction world. One way this is achieved is by closely monitoring project details. GCs also take on a significant amount of risk, and to control that risk they may take actions that result in a restriction to the flow of information.

The consequence of this limitation leads to a traditional construction phase with key design influencers disconnected from the early stages of the project. Unfortunately, there are those within the construction industry who see this as part of their business plan.

Traditions have deep roots, and change is tough

It was almost difficult to collect and communicate efficiently in a collective manner prior to the information revolution of the late 1980s and early 1990s. But even as we are well into an age where it is simple to instantaneously transfer large amounts of data, the deep roots of traditional construction practices are still very much in place.

Engagement is easy, continuous engagement is hard

The application of VDC to a building lifecycle requires very early engagement by all key design influencers and builders. It also requires sustained engagement through the construction phases. As designs become more complex and require many months to construct, this is not an easy undertaking. As with any endeavor worth doing, one must be disciplined, stick to the process, and see it through.

Your business will have greater visibility into each project.

Among VDC’s key advantages is its ability to provide participants with visibility into broad data set at every stage. This deep dive into project data helps all contractors identify threats early in the design process rather than on the job site and prepare for them. Early planning allows projects to go as accurately as possible, which can greatly minimize rework, time spent on RFIs, and many other issues that too often cause delays in schedule and cost overruns.

This early insight into a project also can help specialty contractors see additional areas where their expertise can add value, opening access to new opportunities and new markets. Project stakeholders gain useful options in this situation, while contractors gain extra opportunities to contribute to the project.

Your business will be involved much earlier in each project.

The use of VDC requires contractors to rethink certain procedures and adapt to a new level of collaboration. While VDC adoption can help contractors secure more high-level work, it also impacts the length of time spent on a single project. Early involvement demanded by VDC means longer gestation periods for projects.

Related Blog: Why BIM Adoption for General Contractor is Must?

Longer project durations may also impact management processes and systems. For example, contractors may find that they need a different data management plan for this long time to support their communication channels. Contractors will need to be mindful of changes to the distribution of resources and adjust their procedures accordingly.

Your team will need to develop new skills.

Within a VDC platform, the resources needed to work efficiently are likely to be different from those that most contractors currently have in place, so this change would entail new systems.

The team would need to interpret data in a particular way. As a result, contractors will also find that their workers need to be retrained or bring in new practitioners with skills that match these new needs.

“The biggest change is that the demand for information begins much earlier in the project. Instead of identifying issues (coordination or design) through the construction cycle, they are now identified in the coordination phase.”

— David E. Quigley, Achieving Spatial Coordination Through BIM

What VDC Means to the Industry as a Whole?

Early adopters have an opportunity to lead.

Implementing technology to adopt collaborative VDC processes is the low hanging fruit to start addressing owners’ concerns. The demand for HVAC is marginally ahead of the rest of the AEC industry in VDC implementation. For 15 years or more, many HVAC designers and contractors have been modeling in 3D.

Related Blog: BIM for MEPFP Designers

There is an opportunity to become an expert on this approach, and to be in high demand as an asset to the overall construction process. Plus, the barriers to VDC entry are being reduced substantially faster than in the past.

Late adopters are putting their business at risk.

VDC has the drastic ability to alter the way the construction world operates. Late adopters run the risk of falling so far behind that they eliminate themselves from the market. This is already a reality in several markets. Investing in VDC training is a must for contractors looking to position themselves for success in the ever-evolving industry.

Legal structures will require VDC as the norm.

Owners turn to alternative project delivery methods in frustration with the expense, time, or efficiency of their building. According to Matt Cramer, president of Dee Cramer, a Michigan-based HVAC, and sheet metal contractor, VDC is a baseline requirement for IPD projects and is also commonly expected on large HVAC design-build and design-assist contractual arrangements.

Projects will demand more labor hours—but the work will look different.

In fundamental ways, the essence of work throughout the sector will change. Contractors will spend more time collaborating on a single, integrated model than they will be reproducing drawings, creating separate fabrication models, and working on site.

Lean concepts allow the team to design it once and design it correctly, avoiding useless RFIs and change orders caused by unclear drawings.

Conclusions

- Engage with others in the VDC community. Consider taking a training course from a contractor in a related field to understand not only VDC tools but also the modifications the contractor has made to their business processes. Exposure to this modern way of working is a good first step to learning how unique advantages can be applied to chosen projects.

- Get involved in a construction project at the earliest stage possible. It shows to potential collaborators that you are trying to give future ventures a new level of importance.

- Explore how VDC has been used by other groups within AEC. A good place to find insights into making this turn is the mechanical, electrical, and plumbing (MEP) trade. Many designers of complex MEP systems saw early on how VDC could help them improve designs and reduce clashes among systems.

- Consider hiring a BIM-trained engineer or architect. This professional will help get the business started on its VDC journey and inform those within your organization on what kind of training and support could be required to eventually turn the business into a data-driven services company and advocate for VDC.

- Outsourcing to a good BIM/VDC partner is an option where you can get all the VDC support required from the design phase itself to the final construction phase. Here, the BIM partner will be collaborating with all the team members for you to take care of your modeling and coordination needs while letting you focus on the client. At United-BIM Inc., we aim to deliver peace of mind and value through quality, speed, and consultative approach.

References

In this article, we have taken references to published materials by various experts and researchers. We have credited them throughout the article to acknowledge their work.

For those who like to get into details, we recommend reading the following references.

- Virtual Design and Construction in Practice: A concept paper developed in collaboration with A. Zahner Company for the SMACNA community.