Last updated on: August 1, 2025

Table of Contents

- What is a Digital Twin?

- How Does a Digital Twin Work?

- Types of Digital Twins in Construction

- Core Components of a Digital Twin

- BIM vs Digital Twin: What’s the Difference?

- Applications of Digital Twins in Design-Build Projects

- Need Help Implementing Digital Twin Technology?

- How AI and Machine Learning Are Shaping Digital Twins

- How AI and Machine Learning Are Shaping Digital Twins

- Market Trends for Digital Twins in Construction

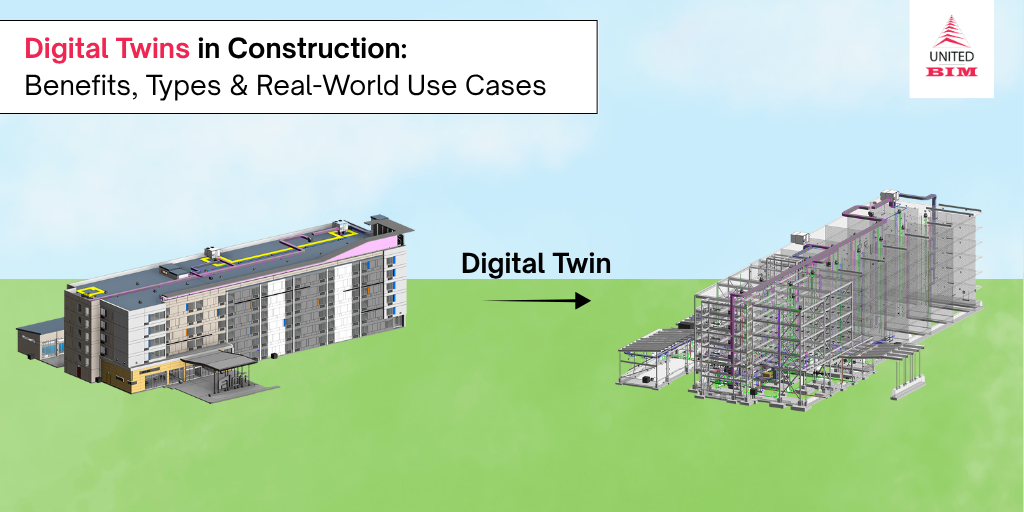

Many of you might have stumbled upon this term – “Digital Twin.” Have you wondered what this digital twin means? Well in layman’s language, a Digital Twin is a digital/virtual replica of a physical entity.

Does Digital Twin always mean a BIM Model? Not always.

BIM (Building Information Modeling) is an integral part of a Digital Twin but the concept is much broader. The functionality of a BIM Model is to replicate the physical asset along with its properties as per the Level of Detail. However, there are some key differences. A Digital Twin relates to the physical world – a “digital thread.”

What is a Digital Twin?

A Digital Twin is a digital model of a building that collects real-world information and creates high-fidelity prototypes of the building via technology like sensors, drones, lasers, and other wireless technology.

The “twin” gathers information from multiple sources like analytics, algorithms, and artificial intelligence to continuously gain insights about the performance, operation, or efficiency of the project, whether built or in progress.

It goes beyond the simulation to help the users understand what is happening in the real world. Real-time reporting is the best advantage for carrying out simulations and considering hypothetical scenarios before putting resources into a new project.

Have any doubts? Let us know. Team United-BIM would be happy to assist you.

Drop us a mail, or Talk to us directly – (860) 317-7105

How Does a Digital Twin Work?

To understand the value of a digital twin, it’s helpful to explore how it operates in a real-world construction environment.

A digital twin works by synchronizing a virtual model with its physical counterpart through a stream of continuous data. Here’s how the process typically works:

- Model Creation: A detailed BIM model of the asset is developed.

- Sensor Integration: : IoT sensors are embedded in physical components like HVAC systems, lighting, and structural elements.

- Data Capture : These sensors capture data on temperature, pressure, vibration, energy usage, and more.

- Data Analysis: : Artificial intelligence and machine learning algorithms process this data to offer actionable insights.

- Continuous Feedback : The model evolves over time based on real-world changes, usage patterns, and environmental conditions.

This process allows the digital twin to reflect the actual state of the building at any point in time and support decision-making at every phase.

Types of Digital Twins in Construction

Now that we understand how it works, let’s explore the different forms digital twins can take in the construction industry. Each type serves a distinct purpose depending on the stage of the building lifecycle.

- Design Twin : Focuses on validating design choices through simulation and early-stage analysis.

- Construction Twin : IoT sensors are embedded in physical components like HVAC systems, lighting, and structural elements.

- Operational Twin : Monitors and optimizes building performance, energy consumption, and maintenance post-handover.

- Predictive Twin: Uses AI to forecast future behaviors, failures, or usage trends, enabling proactive decision-making.

- Federated Twin : Combines multiple systems (HVAC, structural, electrical) into a unified ecosystem for large or complex facilities.

Choosing the right type of digital twin depends on the project phase and the information needs of the stakeholders.

Core Components of a Digital Twin

Behind every effective digital twin is a system of integrated components working together to bridge the physical and digital world.

- Physical Asset : The real-world building or system.

- The Virtual Model : A dynamic BIM model that updates with live data.

- The Digital Thread : A continuous data stream from the asset to the model, powered by IoT and cloud technologies.

This structure allows for a responsive and intelligent digital environment that adapts to real-time changes.

BIM vs Digital Twin: What’s the Difference?

This is a common question, and an important one. While BIM and digital twins are closely related, they are not the same.

| Feature | BIM | Digital Twin |

|---|---|---|

| Scope | Design and coordination | Real-time building performance |

| Data Type | Static or design-phase data | Real-time operational data |

| Updates | Manual or milestone-based | Automated and continuous |

| Usage | Pre-construction and coordination | Construction and post-handover |

Digital twins extend the functionality of BIM by bringing models to life with data intelligence.

Applications of Digital Twins in Design-Build Projects

When applied correctly, digital twins provide immense value throughout the project lifecycle.

- Pre-construction SimulationAnalyze energy performance, airflow, lighting, and safety before building begins.

- Construction Monitoring: Compare planned progress with real-time site data.

- Facilities ManagementUse live data for system monitoring, preventive maintenance, and energy savings.

These applications help reduce risk, improve coordination, and extend the life of the building asset.

How AI and Machine Learning Are Shaping Digital Twins

Adding another layer of intelligence, artificial intelligence and machine learning are rapidly advancing the capabilities of digital twins.

These technologies can:

- Predict maintenance needs before systems fail

- Detect anomalies in HVAC or electrical systems

- Simulate building performance under different environmental conditions

- Recommend energy-saving actions based on usage trends

AI transforms digital twins from reactive systems into proactive tools that help reduce downtime and improve long-term efficiency.

How AI and Machine Learning Are Shaping Digital Twins

Adding another layer of intelligence, artificial intelligence and machine learning are rapidly advancing the capabilities of digital twins.

These technologies can:

- Predict maintenance needs before systems fail

- Detect anomalies in HVAC or electrical systems

- Simulate building performance under different environmental conditions

- Recommend energy-saving actions based on usage trends

AI transforms digital twins from reactive systems into proactive tools that help reduce downtime and improve long-term efficiency.

Market Trends for Digital Twins in Construction

The demand for digital twins is growing steadily as more firms see their operational value.

Here are some key trends shaping the future:

- The global digital twin market is expected to reach USD 149 billion by 2030.

- Increased focus on green buildings and energy efficiency is driving adoption.

- Smart cities and infrastructure projects are integrating digital twins for data-driven planning.

- Wider access to cloud computing and IoT devices is reducing implementation costs.

Construction companies that embrace digital twins early are more likely to stay ahead in performance, compliance, and client satisfaction.

Conclusion

Digital twins are rapidly becoming a cornerstone of smart construction and facility operations. By combining BIM, IoT, AI, and real-time analytics, digital twins offer a more dynamic and intelligent way to design, build, and manage buildings.

At United-BIM, we specialize in helping AECO professionals implement digital twin solutions that drive efficiency and value.

Need help implementing a digital twin for your next project?

Contact us today or call (860) 317-7105 to learn how we can help.

A digital twin example in construction could be a smart hospital where the HVAC, lighting, and medical equipment are connected through sensors. The digital twin collects real-time data to monitor performance, detect faults, and plan predictive maintenance all from a virtual model.

The four common types of digital twins in construction are:

1. Design Twin – Validates design decisions using simulations.

2. Construction Twin – Tracks real-time progress and deviations during the build.

3. Operational Twin – Optimizes building performance post-construction.

4. Predictive Twin – Uses AI to forecast future system behaviors or failures

BIM (Building Information Modeling) is used to create and coordinate detailed design and construction models. A digital twin, on the other hand, connects that model to real-time data through sensors and IoT, turning it into a living, constantly updating system used for performance monitoring and facility management.

Digital twins are valuable for a wide range of professionals in the AEC industry including:

• Architects for simulation and design validation

• Contractors for real-time construction tracking

• Facility Managers for ongoing monitoring and predictive maintenance

• Building Owners for cost control and lifecycle optimization

Yes. In a commercial high-rise, a digital twin can integrate sensor data from elevators, HVAC systems, energy meters, and access control. This helps the operations team monitor real-time conditions, predict system failures, and reduce energy consumption—all through a central digital platform.

About the Author

Coordination Manager / VDC Manager at United BIM

With over 10 years of experience in the AEC industry, Akash Patel is a seasoned Coordination Manager and VDC Manager at United BIM. His expertise lies in managing complex MEP-FP coordination projects and leveraging cutting-edge BIM technology to ensure seamless collaboration and precision. Akash is dedicated to delivering high-quality, detailed models that meet the demands of modern construction. He is passionate about optimizing workflows and driving innovation within the BIM field.