Last updated on: October 17, 2025

The construction industry is evolving rapidly. Increasing project complexity, tighter schedules, and budget constraints are pushing architects, engineers, and contractors to explore methods that optimize resources, reduce waste, and accelerate delivery. Traditional on-site construction often faces delays due to weather, labor shortages, and coordination inefficiencies, resulting in cost overruns and schedule slippage.

Offsite construction currently represents a about 6–8% of global construction activity, but adoption is growing rapidly. In the U.S., the modular construction market reached $20.3 billion in 2024, roughly 5.1% of total construction, and is projected to grow to $25.4 billion by 2029, reflecting a CAGR of ~4.5%. This growth signals a clear industry shift toward industrialized construction methods that emphasize speed, quality, and predictability.

Prefabrication in Modern Construction

The construction industry is evolving rapidly. Increasing project complexity, tighter schedules, and budget constraints are pushing architects, engineers, and contractors to explore methods that optimize resources, reduce waste, and accelerate delivery. Traditional on-site construction often faces delays due to weather, labor shortages, and coordination inefficiencies, resulting in cost overruns and schedule slippage.

Prefabrication in Modern Construction

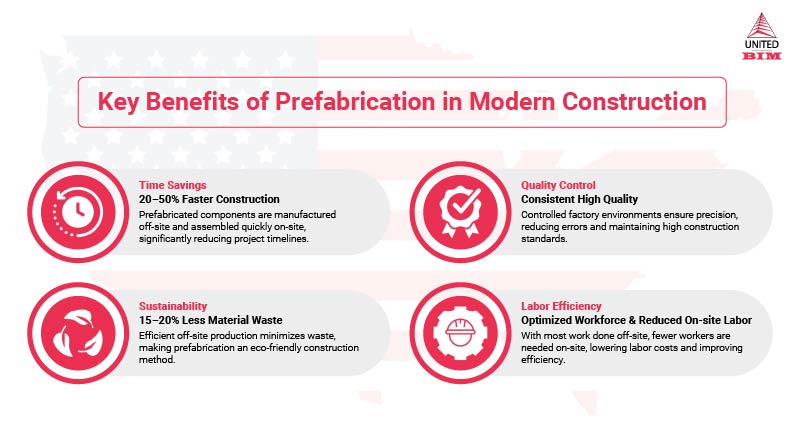

- Time Savings : Off-site production allows site preparation to occur concurrently, shortening overall schedules. Studies indicate modular projects can be 20–50% faster than traditional methods.

- Quality Control : Factory conditions ensure consistent quality and protection from climate extremes.

- Sustainability : Standardized components and BIM coordination reduce waste, with studies showing 15–20% less construction waste compared to conventional builds.

- Labor Efficiency : Fewer skilled workers are needed on-site as prefabricated modules arrive ready for assembly.

While prefabrication focuses on off-site assembly of individual components, modular construction entails larger-scale deliverables, such as entire rooms or volumetric units. The scale of modularization increases coordination complexity: every element must integrate precisely with adjacent modules.

BIM supports modularization in the same ways it supports prefabrication: clash detection, digital sequencing, and lifecycle tracking ensure that larger, more complex modules fit seamlessly into the project, reducing the risk of costly adjustments on-site.

Challenges of Prefabrication and Modularization

Despite its advantages, offsite construction introduces unique challenges:

- Lead-Time Dependencies: Manufacturing and delivery schedules must be finalized early, putting pressure on design decisions.

- Coordination Complexity: Multi-trade alignment is critical to prevent clashes during assembly.

- Logistics Constraints: Transporting large or delicate components requires careful planning.

- Limited On-Site Flexibility: Design or fabrication errors are difficult to correct once components are produced.

These challenges underline the importance of digital coordination and predictive planning, areas where BIM has been providing measurable impact.

How BIM Enhances Prefabrication and Modular Workflows

BIM is central to mitigating prefabrication and modularization risks, providing a digital, data-rich representation of the building that enables visualization, simulation, and optimization before production or installation.

1. Design Accuracy and Early Coordination

Parametric and rule-based modeling for prefab precision

- BIM enables creation of intelligent, parametric components that automatically adjust to fabrication constraints while following predefined design rules.

- Each element, walls, MEP racks, or structural modules is designed to fit precisely into the prefabricated assembly, reducing errors and ensuring compliance with industry standards.

Early collaboration with manufacturers

- Manufacturers’ input on tolerances, materials, and assembly sequences is integrated directly into the BIM model.

- Prefabricated elements are virtually validated for fit and function, preventing costly adjustments on-site.

Clash detection and fabrication readiness

- Clash Detection identifies potential conflicts between architectural, structural, and MEP systems before fabrication begins.

- Produces accurate, fabrication-ready models that can be directly used for off-site production and streamlined installation.

2. Mitigating Lead-Time Challenges

Early design decisions for prefab elements

- Prefabricated components, such as MEP racks, wall panels, or volumetric modules, often have long manufacturing and delivery lead times.

- Making design decisions early is critical to avoid delays in production and on-site installation.

Virtual simulation and clash validation

3. Industrialized Construction and Workflow Optimization

BIM-enabled factory integration

- BIM facilitates digital fabrication workflows by connecting the design model directly to CNC machines, robotic assembly systems, and offsite production lines.

4D scheduling and workflow sequencing

- By leveraging 4D BIM scheduling, project teams can align fabrication, transportation, and on-site installation sequences. This enables simulation of delivery paths, crane operations, and assembly order, minimizing bottlenecks and idle time while ensuring smooth coordination across all trades.

Predictable allocation and site efficiency

- Accurate planning of equipment and site resources becomes possible when BIM integrates production and installation data. This ensures teams know exactly when and how components arrive and are installed, improving safety and efficiency while reducing on-site guesswork.

4. Labor Efficiency and Site Productivity

Reduced on-site workforce

- Off-site prefabrication minimizes the number of trades/labors required on-site at any given time, reducing congestion and streamlining operations.

BIM-guided clarity and safety

- Digital models and visual instructions from BIM provide clear guidance for installation, enhancing safety and reducing errors during complex assembly tasks.

Confident and efficient teams

- Teams can execute installations with greater confidence and fewer mistakes, lowering stress and improving overall productivity.

5. Quality Control and Waste Reduction

Clash detection and tolerance management

- BIM identifies potential conflicts between architectural, structural, and MEP systems early, preventing costly on-site rework and ensuring prefabricated components fit perfectly.

Optimized material usage

- Accurate, model-based quantities allow precise ordering of materials, reducing overuse and minimizing construction waste.

Proven efficiency gains

- Industry analyses report up to 20% cost savings and 15–20% reduction in waste when prefabricated and modular workflows are integrated with BIM, demonstrating both environmental and financial benefits.

6. Lifecycle Integration and Facility Management

- COBie data and asset tracking provide visibility of prefabricated and modular components throughout the building’s lifecycle.

- Enables maintenance planning and post-occupancy operations with accurate, model-based records.

- BIM ensures interventions are targeted and informed.

Conclusion

BIM acts as the digital backbone, bridging design, fabrication, and site assembly, and ensuring that complex modular units integrate flawlessly.

Beyond technical precision, BIM provides a human dimension: teams experience reduced stress, improved collaboration, and greater confidence in execution. When paired with offsite construction methods, BIM doesn’t just enable faster building, it allows construction teams to build smarter, safer, and more predictably, turning industrialized construction from a promising concept into a practical, high-performance reality.

If your project involves prefabrication or modular construction, BIM is essential for ensuring efficiency, accuracy, and coordination. United BIM provides seamless BIM services tailored for offsite construction workflows. Contact us today to streamline your next project.

About the Author

Coordination Manager / VDC Manager at United BIM

With over 10 years of experience in the AEC industry, Akash Patel is a seasoned Coordination Manager and VDC Manager at United BIM. His expertise lies in managing complex MEP-FP coordination projects and leveraging cutting-edge BIM technology to ensure seamless collaboration and precision. Akash is dedicated to delivering high-quality, detailed models that meet the demands of modern construction. He is passionate about optimizing workflows and driving innovation within the BIM field.